Ireland is the location of choice for over 90% of the world’s top pharmaceutical companies & has become the eighth largest producer & the fifth largest exporter of pharmaceuticals. Pharmaceuticals make up 50% of all of Ireland’s manufactured exports, with Active Pharmaceutical Ingredients (APIs) forming the backbone of the sector.

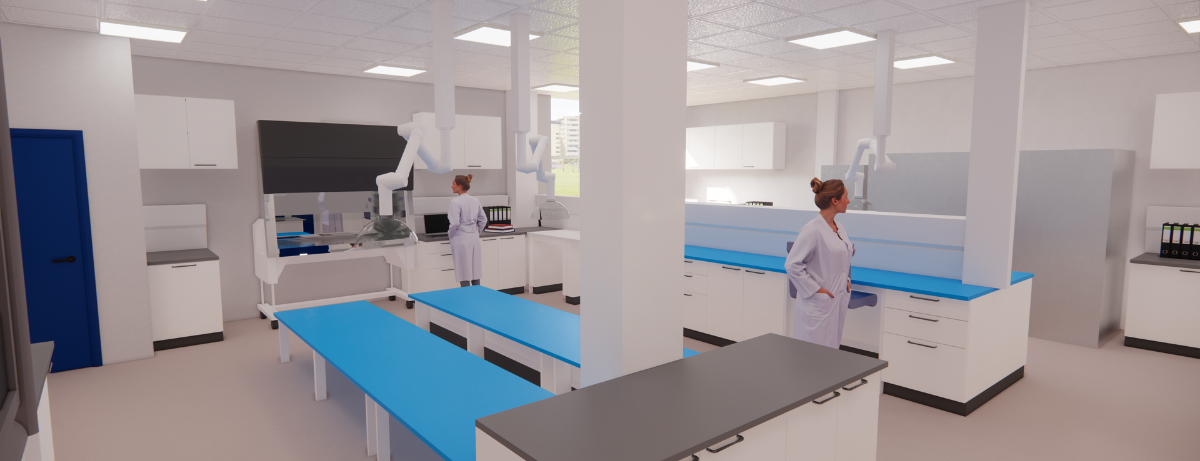

Tandem’s team bring a wealth of experience to delivering successful project outcomes. Its Project Managers, Project Controllers, Design Engineers, Construction Managers & CQV Specialists have extensive life-sciences experience, having worked with many of the top API companies. This expertise allows our clients to deliver consistent controlled manufacturing to required standards.

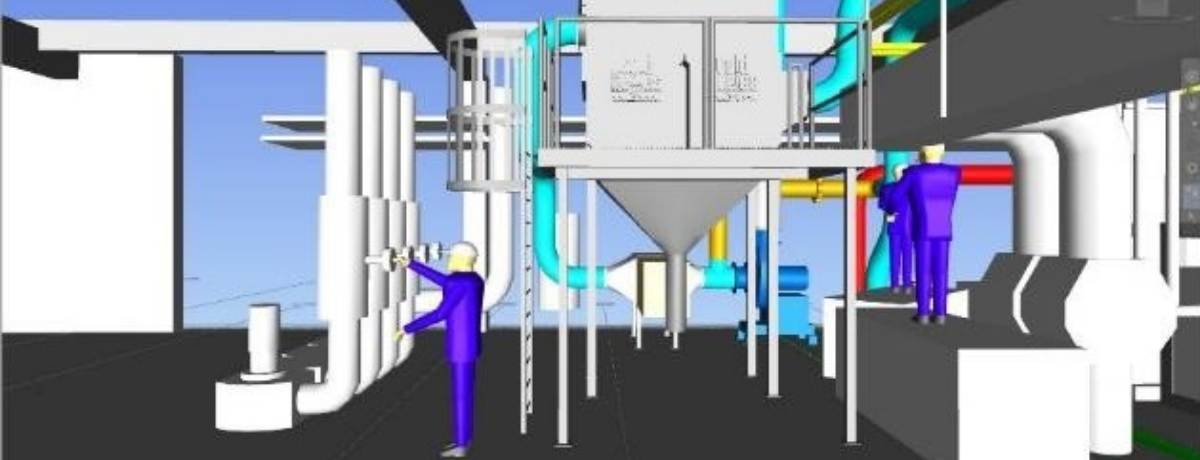

Tandem delivers expertise to your entire project life cycle in all areas of design including process, process architecture, equipment, facility, cleanroom, clean & black utilities, HVAC & building services, electrical & instrumentation, process automation & building management systems. We also provide specialist Health & Safety services, such as Risk Assessments, HAZOP, ATEX/ EPD, pFMEA, & the full range of construction safety requirements, including BCAR Certification, PSDP & PSCS.